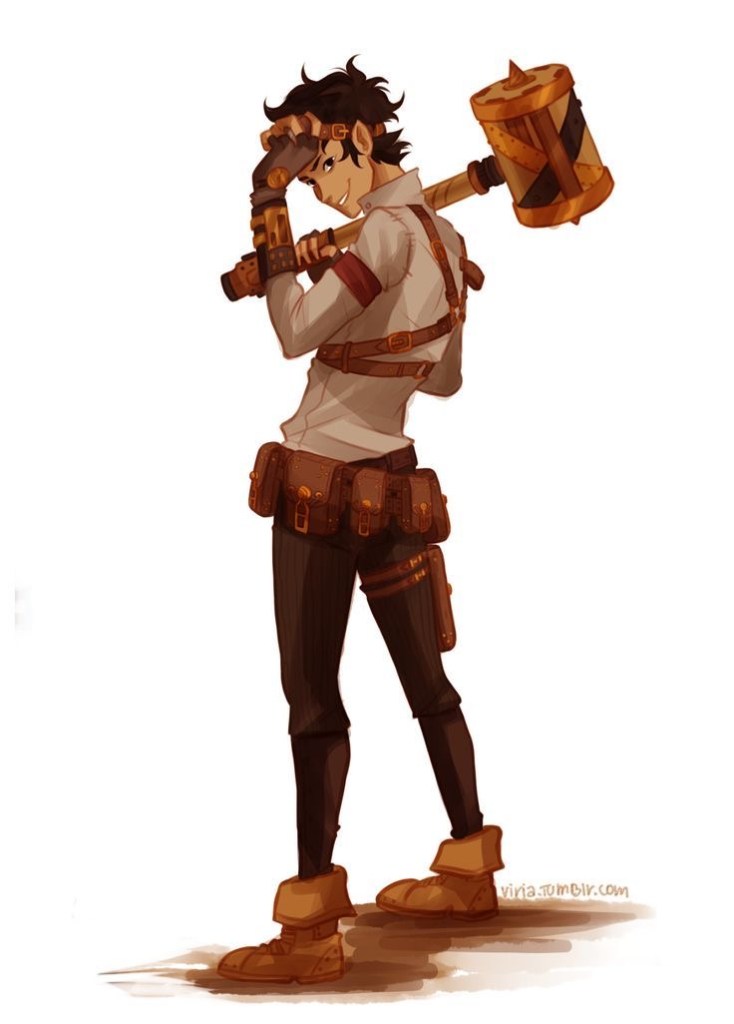

Max read the Percy Jackson books and keen on the idea of being one of the characters for his first cosplay. Leo Valdez was the character Max wanted to be.

The primary prop was a big forge hammer. We made it mainly from EVA foam and it was a fun build. Two things I will highlight is the wooden handle technique and how to create the squaricle hammer head shape.

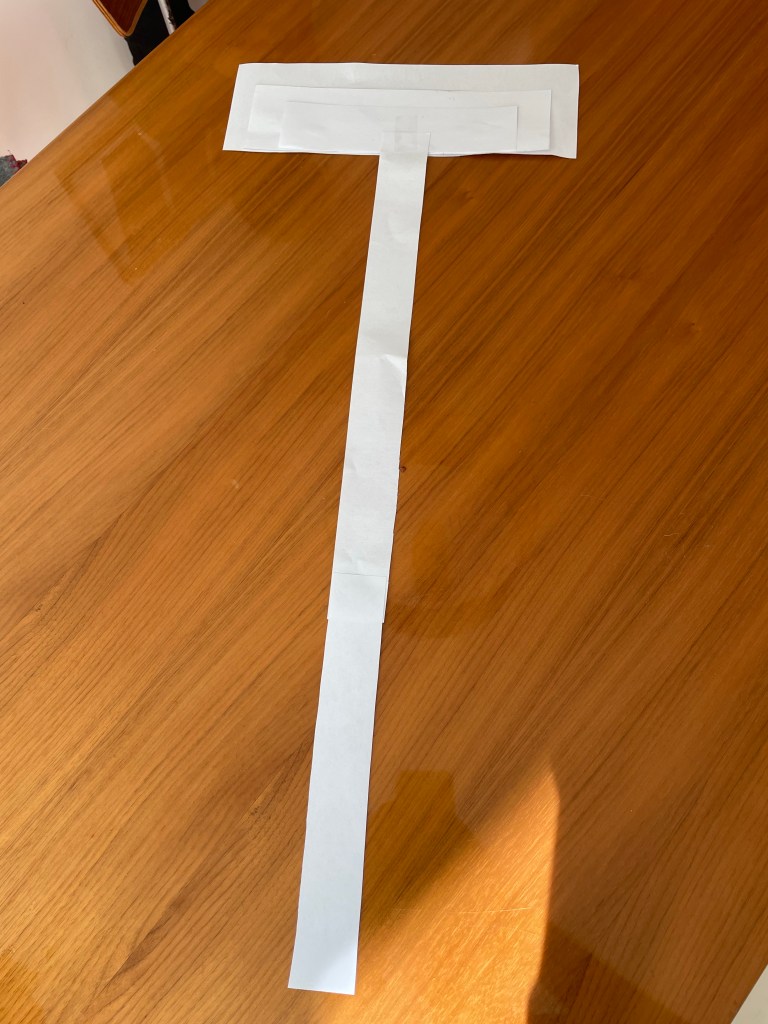

Firstly to get the right sense of scale, we started with a regular sledgehammer from amazon, biggest one we could find, which was 16lbs, over 7kg. Then made a paper plan of that and gradually scaled it up to a suitably heroic scale. We got Max to hold it to check sizing and went for the largest of the three templates below.

The hammer head ended up being larger than Max’s head, but it looked great and he got quite a few complements.

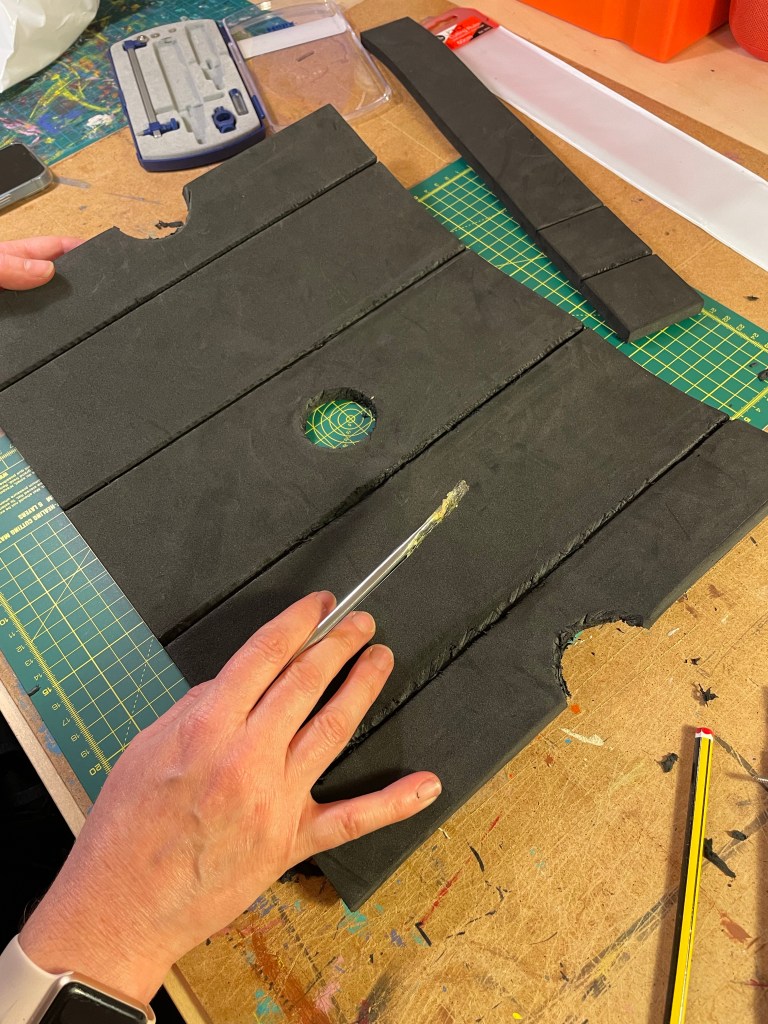

To get the hammer head right shape we looked at blacksmiths forging hammers, like this one from etsy. A lot of templates for cosplay hammers use individual panels to create the hammer head, but using one piece of foam made the hammer feel more like a tool. No seams showing or joins in the foam.

The template meant each side was about 10cm in size, so we cut a single piece of 10mm eva foam and then cut a v-shaped section out of the foam to allow it to fold and have nearly 90 degree angles. You can see the test strip we did the initial prototyping on above the flattened out hammer head. Contact adhesive (I like Alpha Thixofix) helped the foam take its shape and then affixed it to the handle.

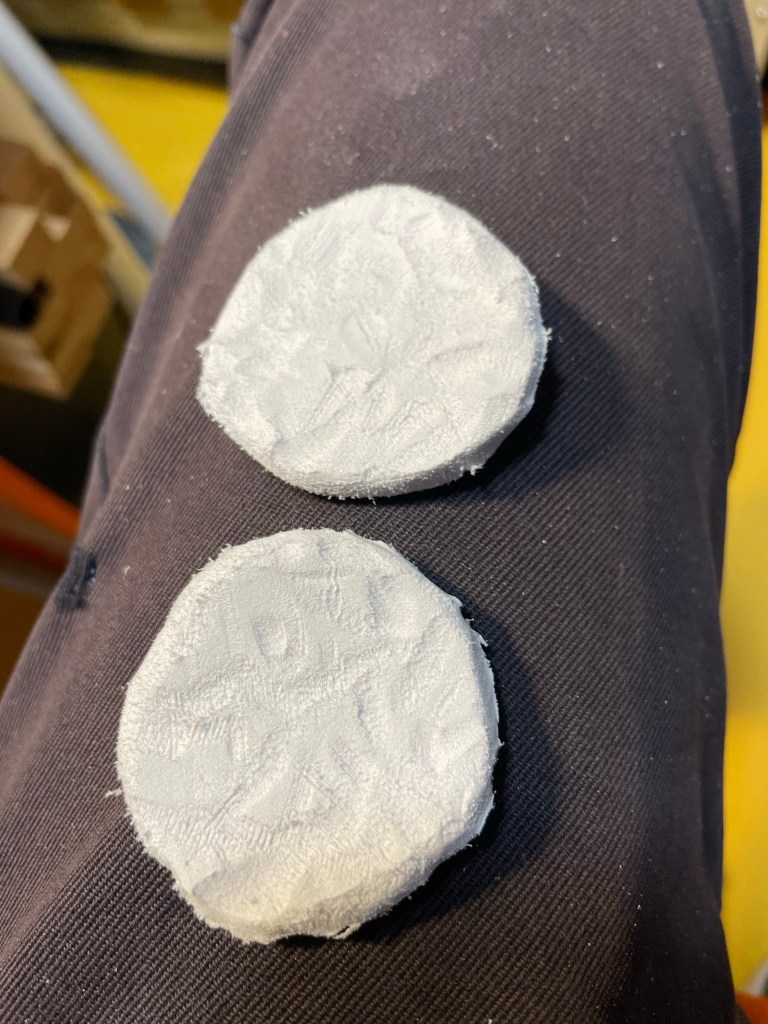

We added a second layer of foam inside the head to make the connection area between the head and the handle larger. The last part of the hammer head were the faces for the hammer and the ends of the handle, the photo below is the top and bottom of the handle before heat-treating, priming and painting.

You can see the hammer head taped up and curing in the photo below.

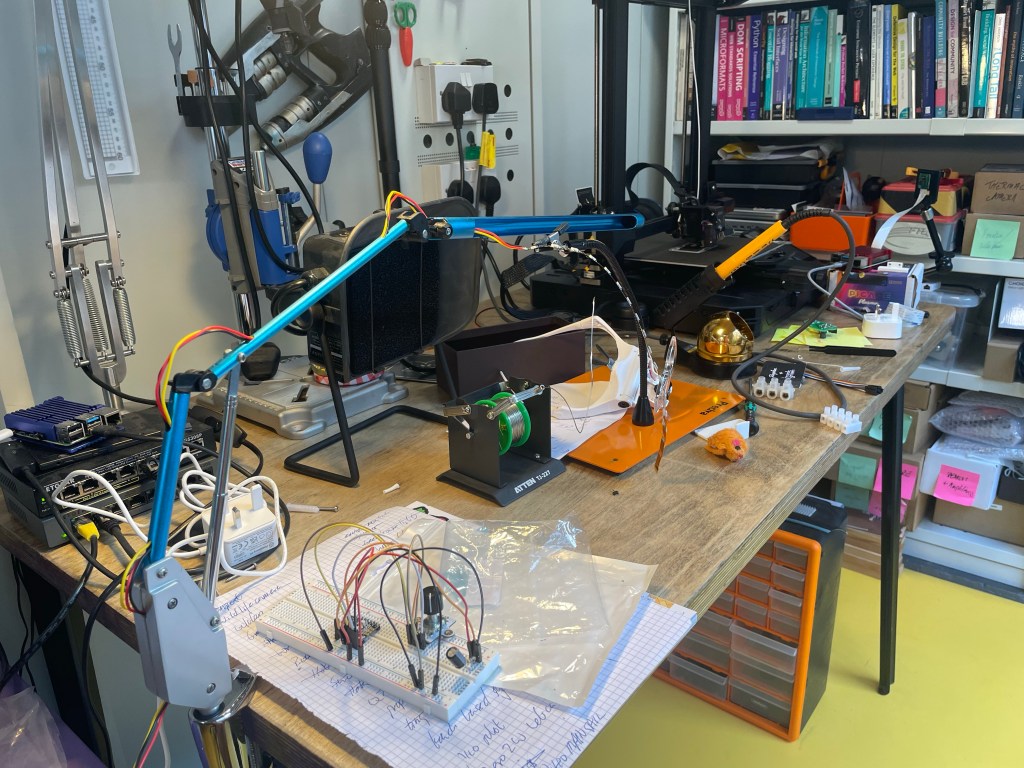

The handle was a piece of plastic pipe which was wrapped in foam. Max did an excellent job of mapping wood grain onto the handle and then carving it with a dremel. The snake handle or Flexible Shaft Attachment is essential for carving EVA foam, it makes the work less tiring, as it is easier to hold. Some safety kit, as you can see in the photos is important too. A set of sealed eye goggles, some breathing kit with the dust and A2 vapour filters and some ear protectors will save your eyes, nose and lungs as well as your hearing from the dremel dust.

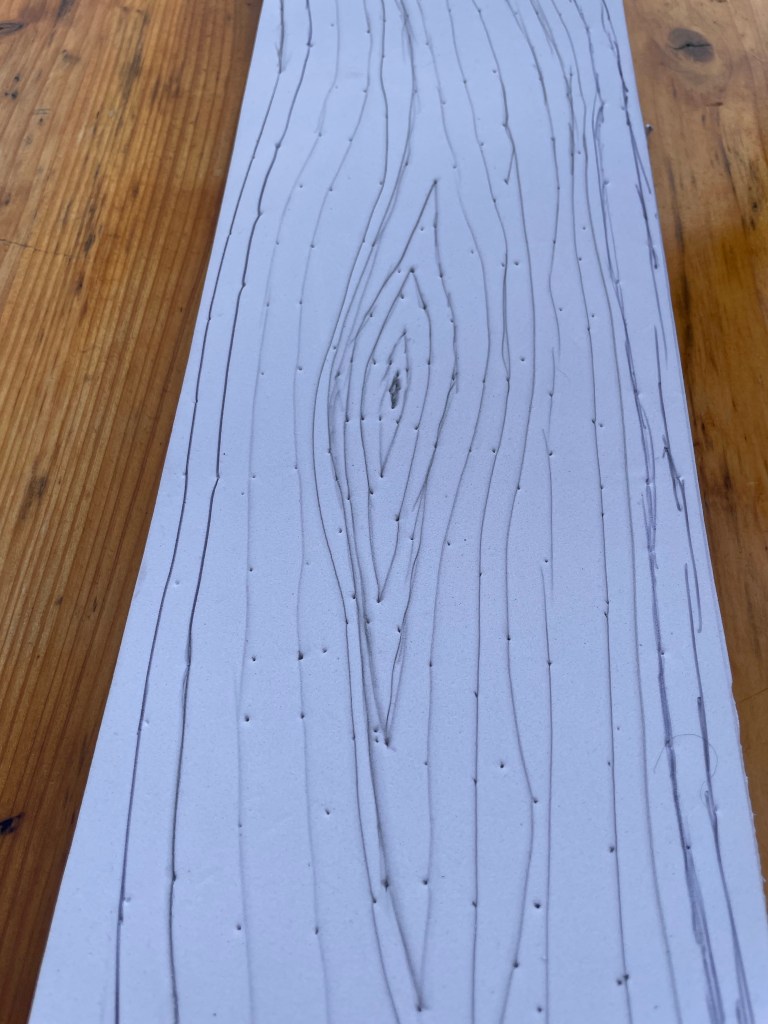

Testing out how to make wood grain

Mapping across the tracing of the wood grain before carving. Max used pins to transfer the tracing from paper onto the foam, which was really effective.

It then got painted and we stuck the handle onto the head of the hammer and added bit of aging to make it look less like it was just made. It would have been good to have more time to do the aging, but the hammer had a final coat of varnish the night before comic-con at 1am!

If this was helpful then you could buy-me-a-coffee.

You must be logged in to post a comment.