We made Max’s Heather costume which was a success, photos coming. My own Dagur costume got parked, as Max needed my help. This has given me time to reflect and approach building Dagur as an open learning process, aiming for May next year. Doing two at the same time was too much pressure on time and space.

There are a huge number of skills that you need to make a cosplay from scratch. I’ve made a few props and some costumes already, but there is still a lot to learn, so I’m going to take advantage of this and document my process as I complete Dagur. I need to work in a sustainable manner, not try to do everything. Con-crunch only gets you so far and some processes, like sealing, priming and painting foam have built in delays for drying.

So far, I’ve traced weapons shapes and armour designs from screenshots from RTTE. I’ve been using Adobe Illustrator and comparing it with Lunacy from Icons8. I’m going to make a video explaining how to trace a pattern from screen to generate a blueprint for an eva foam prop. I know there are some out there, but they seem to show everything quite quickly. So I’m going to slow it down and explain how pen tools work and about Bezier curves for people doing this for the first time.

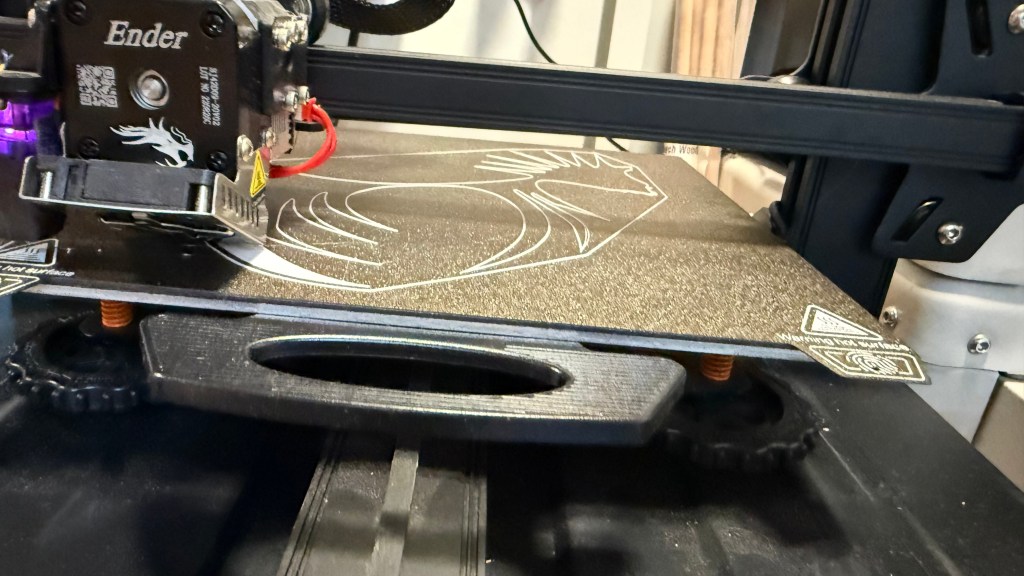

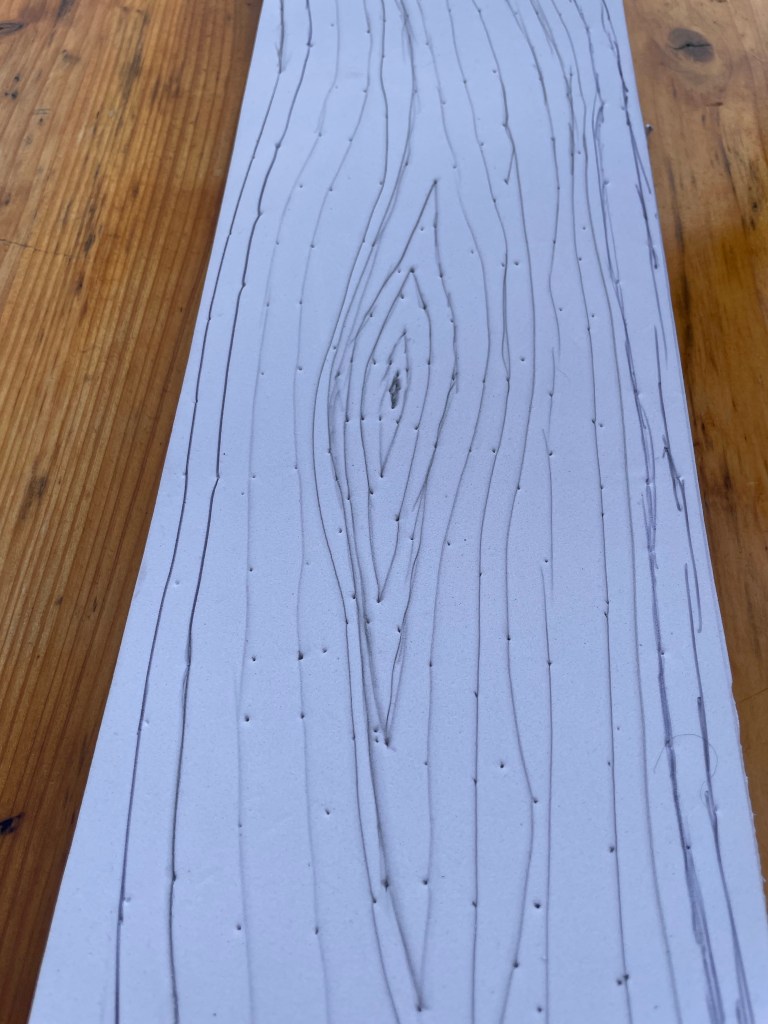

Beyond that, I’ve taken those tracings and made 3d prints from them, in fact the Skrill about became a 3d print, as it is too fine to cut from 2 mm foam.

Then I’ll pull out over the coming weeks tutorials and examples from

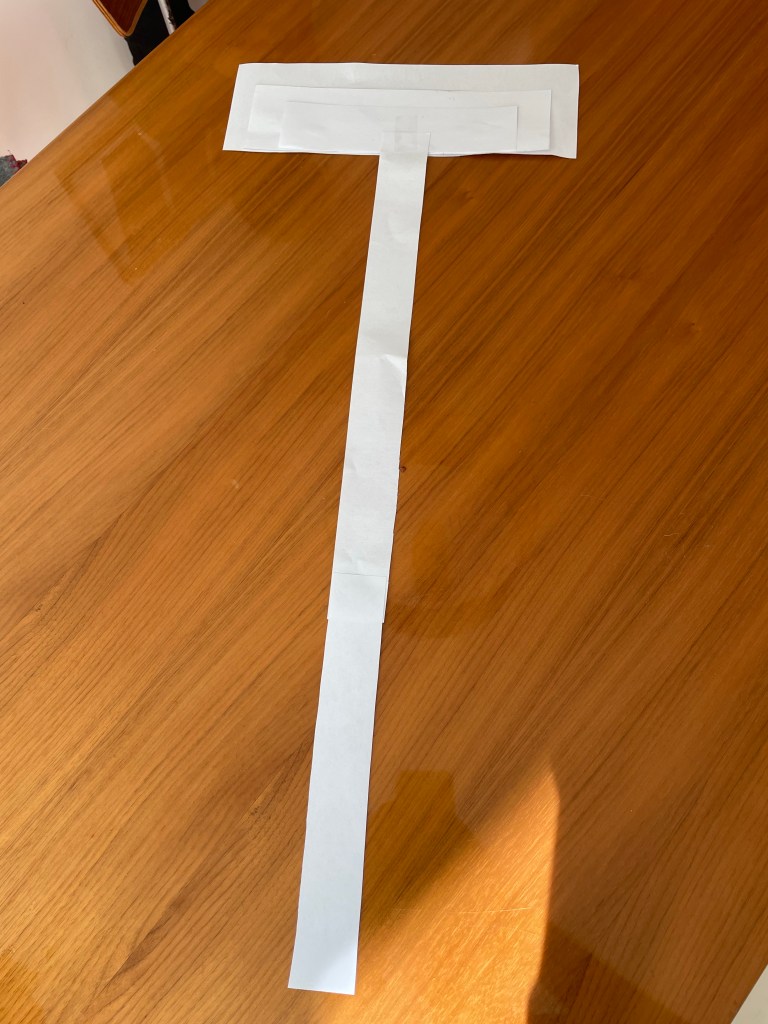

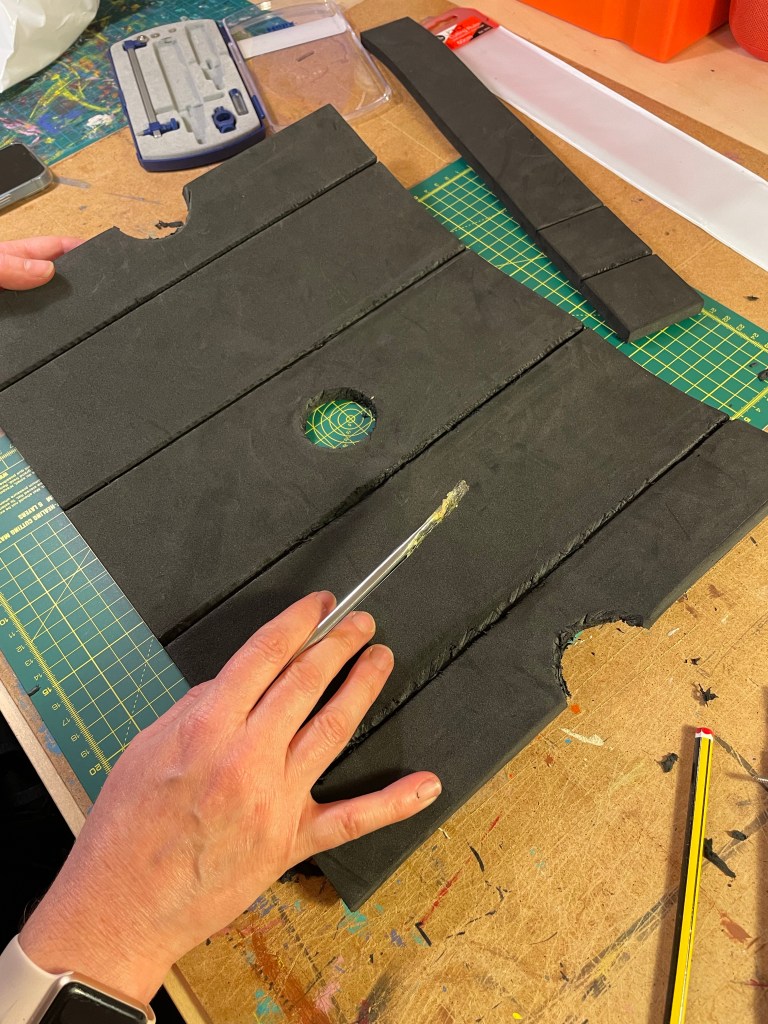

- different approaches to prototyping and pattern design using paper and card

- Foam clay and leather work for belts and straps

- a simple free 3d design workflow to create basic objects and when to use that

- airbrushing, painting and weathering

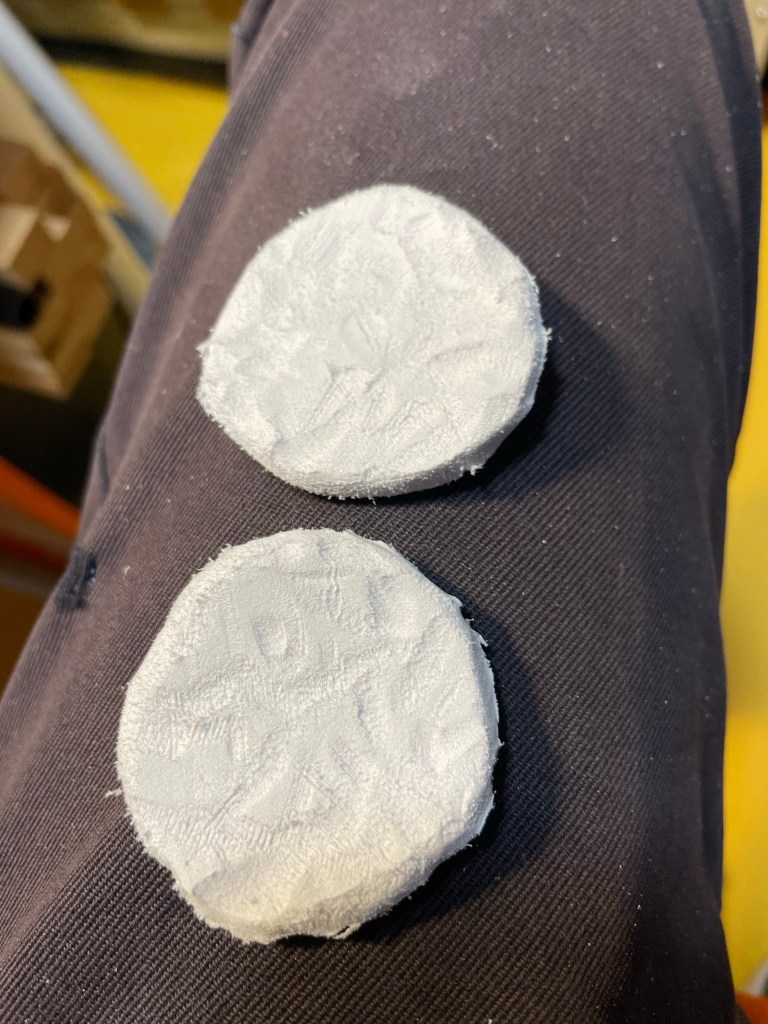

I’ll create samples of these as I go showing the results from each process, as a work towards a finished costume and prop, rather than the focus being the actual finished item. Working in the open and showing my work in progress is the plan, borrowing form my day job.

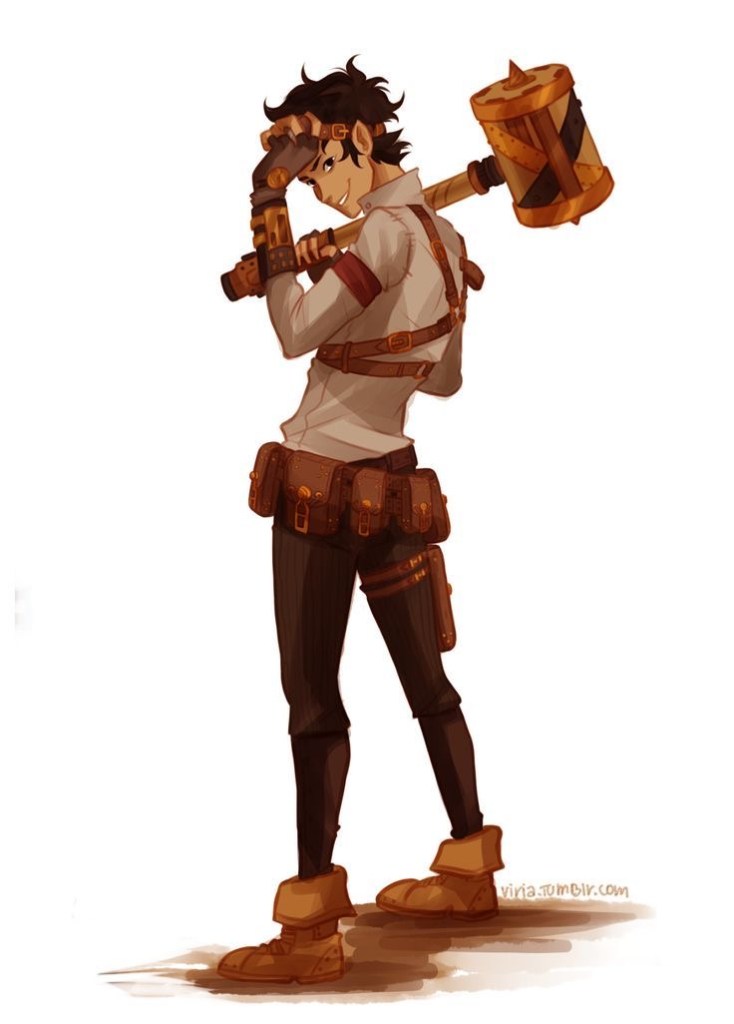

I’m also going to put the patterns I have made up on Etsy, starting with the forge hammer from Leo Valdez.

You must be logged in to post a comment.